After the delivery of the two Noble Globetrotter vessels Huisman further developed the drillship design. This resulted in the HuisDrill 12000. The HuisDrill 12000, as designed with Huisman’s DMPT technology and unique construction methodologies, exceeds many of the capabilities of competing drillship designs.

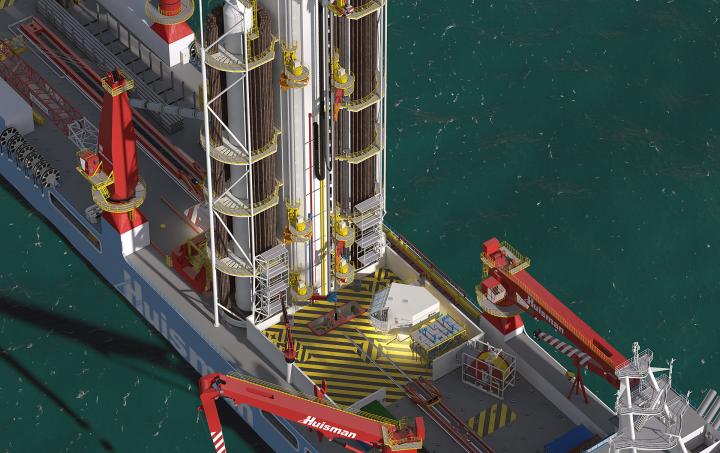

The Huisman approach results in several functional and operational advantages. The vessel has a large functional work deck forward and aft of the tower that is flush with the drill floor. All ventilation, mooring and access ladders are located below this work deck. The vessel is equipped with a DMPT that can handle loads up to 3.6 mln lbs and pipe stands with a length up to 180ft. Further the vessel stores and runs 150ft risers, which minimises the time for running risers. The drilling unit is optimised as a whole. The design of the drilling package, the functionality thereof and the material flows on board are top priority. The design of the vessel is made to optimally accommodate the drilling and completion processes.

These changes in the design result in a vessel size that is 208m x 36.4m with a maximum VDL of 30,000mt. DWOPs have shown that the vessel can drill wells in 75-80% of the time compared with other state-of-the-art units.