Fully Mechanised quadrant handling

The quadrant is fully restrained from the start of the operation until it is released below the splash zone

- Increased weather window

- Controlled and time efficient operation

- Increased safety

Quadrant cursor system

The quadrant handling system is equipped with a cursor system. The quadrant motions are fully restrained until deployed beneath the splash zone

- The cursor system avoids damage to the quadrant

- Reduced catenary dynamics

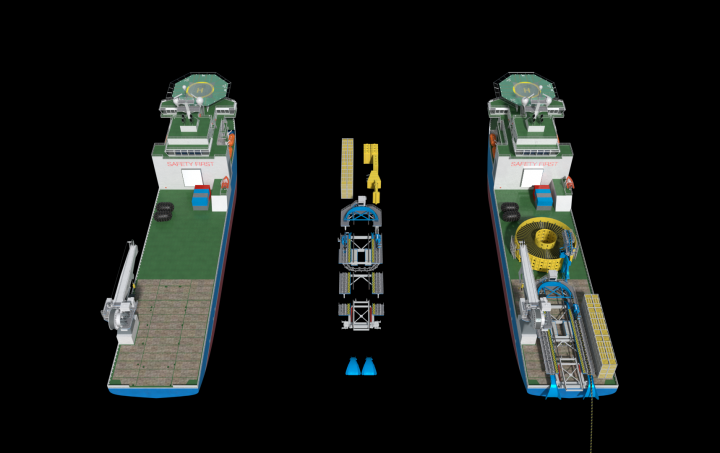

Modular design, short mobilisation time

- The system can be installed swiftly because of its modular design and simple interface

- Can be installed using a single lift

- Integrated power and control systems minimise interconnecting cable with the vessel

Straightening quadrant

The radius of the quadrant can be adjusted from the MBR to straight during lowering

- Cable can be abandoned without uncontrolled drop onto the seabed. Cable tension is controlled during the complete operation

- Quadrant can be retrieved when cable is straight on the seabed avoiding torque variations that can cause cable failure

Controlled touch down point location

Motion compensation keeps the touch down point of the cable within a smaller target box

- A smaller target lane requires less survey and target lane clearing activities

- Dragging of the cable over the seabed, especially when cornering, is avoided.

- Tension variations are reduced and the risk of snagging mitigated.

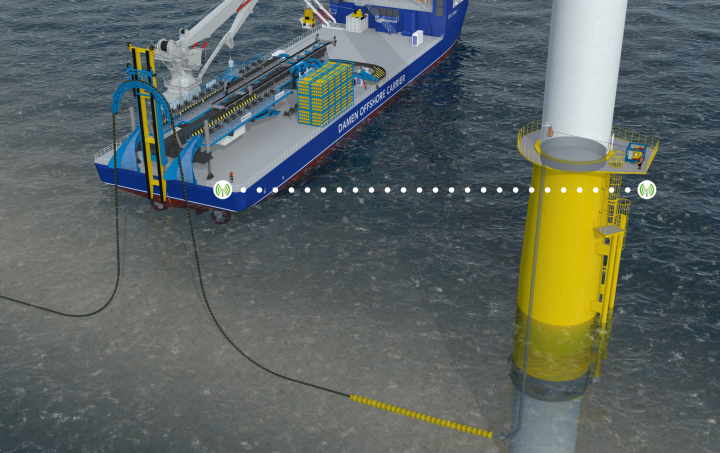

Synchronised pull in winch

Synchronisation of the Pull-in-Winch with the central control system ensures better control of pull-in operations

- Improved tension control avoids overbending or compression in the cable

- Controlled from vessel using a secure data connection

Reruced risk of cable failure during trenching

Motion compensated Cable-Lay reduces the tension variations in the laid cable to a narrow bandwidth facilitating trenching.

Efficient CPS storage system

CPS strings are loaded on board in containers and transferred to the firing line using a gutter system

- Containers allow for easy transport and loading

- Height adjustable ramp to extract a CPS from different elevations

- CPS gutter system independent of cable routing, allowing parallel operations

- Safe access for personnel to containers

Adjustable to cable repair spread

Thanks to its modular design, the Motion Compensated Cable-Lay System can be quickly mobilised and demobilised onto PSV’s and OSV’s, making this system ideal for cable repairs or replacement that need to be carried out throughout the year, as quick as possible. The Motion Compensated Cable-Lay System can be configured for cable repairs. The special features entail extra opening shelters, in which the cable can be repaired.

Motion Compensated Cable-Lay Vessel

Our Motion Compensated Cable-Lay System has been integrated in Damen’s Offshore Carrier (DOC), introducing the world’s first motion compensated Cable-Laying vessel (CLV). Damen and Huisman offer the market a fully integrated solution specifically tuned to optimising operability and improving control and accuracy of cable placement.

Read more