Delivering step

changing solutions

We are Huisman. We design, manufacture and service heavy construction equipment for the world’s leading companies in the renewable energy, oil and gas, civil, naval and entertainment markets. Our products range from Cranes, Offshore Wind Tools, Pipelay and Drilling Equipment to specials.

/ innovations

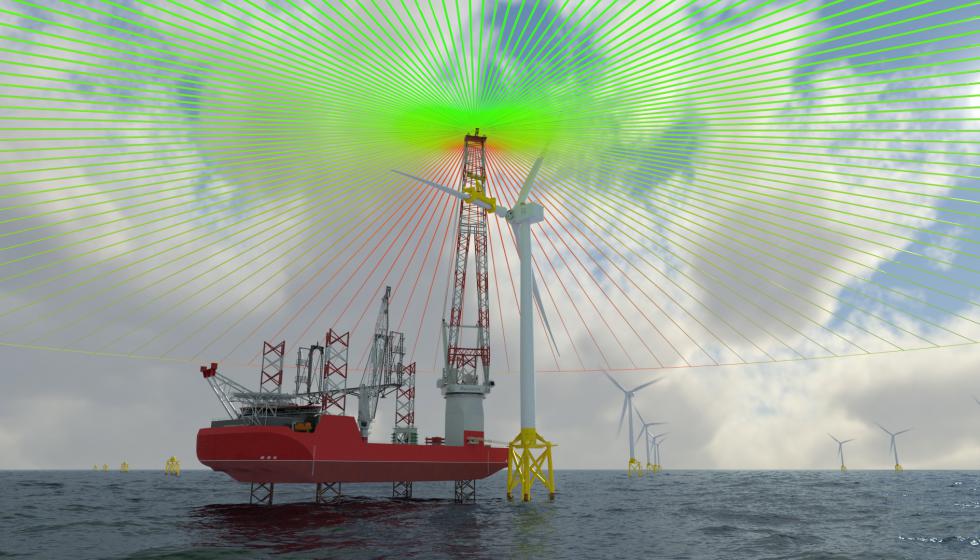

Wind gust buster

Huisman launched of a newly developed system, called Wind Gust Buster to assist crane operators and lifting supervisors when working with the installation of large objects at considerable height, by providing information on the incoming wind 360° around the boom tip.

Read moreTravelling Load Stabilising System

Controlling the movements of the relatively light blades of a turbine when suspended from a crane, has proven to be an installation challenge due to wind load. Huisman and Siemens Gamesa developed the Travelling Load Stabilising System, for universal application in heavy lifting cranes.

Read moreWindfarm installation vessel

To improve the efficiency of offshore windfarm installation, Huisman has developed the Windfarm Installation Vessel (WIV); a semi-submersible vessel with a 3D motion compensated WTG installation system.

Read more

Convertible Pre-Piling Template

With offshore wind farms being built in ever deeper waters, there is a growing demand for jacket foundations to support the increasingly larger Wind Turbine Generators. These jacket foundations come in different designs to accommodate the varying conditions and parameters of the wind farm locations. Huisman introduces the Convertible Pre-Piling Template, an economic and reliable solution for accurate piling.

Read moreMotion compensated platform

Huisman introduces the Motion Compensated Platform to ensure that components can be transferred quickly and safely from a feeder vessel.

Read moreUniversal quick connector

Rigging operations can take up valuable time of your consecutive offshore operations. With the Universal Quick Connector, Huisman offers a safe and efficient solution to reduce your cycle time and mitigate the safety risks of people involved in changing installation tools.

Read moreMotion compensated monopile gripper

The Motion Compensated Monopile Gripper is designed by Huisman to allow monopile installations from a floating vessel while controlling the vertical alignment of the monopile.

Read moreHuisman innovation tower

The Huisman Innovation Tower (HIT) is a 90m high drill tower, with the ability to simulate dynamical vessel movements. The HIT is located at our quayside in Schiedam and is used to demonstrate Huisman drilling equipment, to develop and test future equipment and systems and for the training of operators and Huisman staff.

Read more3D printed crane hook

Huisman actively employs the 3D printing technique ‘Wire & Arc Additive Manufacturing’ (WAAM) to produce mid-size to large components with high grade tensile steel. An important benefit for larger crane hooks is the significant reduction in delivery time at a cost that competes with forgings and castings, and a more consistent level of quality.

Read more/ markets

/ our people

Arnold, Tender & Concepts Engineer

Cees, Product Manager Cranes

Charlotte, Manager Sales New Build

Korneel, Product Manager Innovation

Robin, Principal Engineer

William, Mechanical Engineer

/ global presence